Labelling

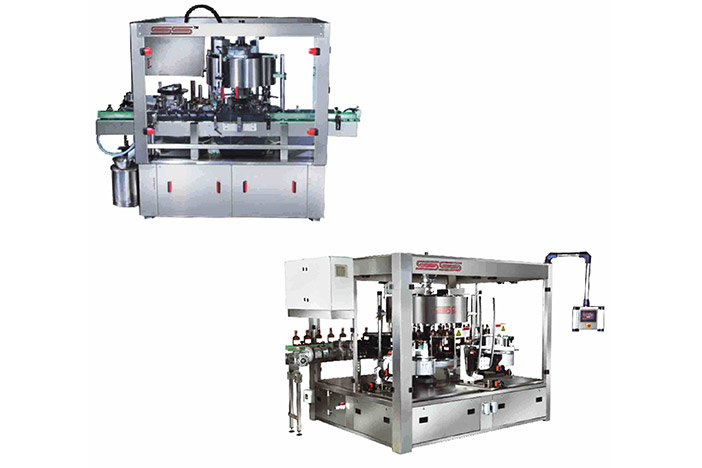

Rotary Labeller

This machine is a high speed rotary type machine with output ranging between 2,000 – 18,000 bottles per hour and can handle different type and size of bottles and labels. Multimatic is very efficient and can handle all type of glass and plastic bottles / containers ( cylindrical / non-cylindrical & odd shaped) with various pressure sensitive labelling applications.( 1 – 5 labelling station options)

Label Type:

- Self-adhesive

- Wet glue

Label Positions:

- Front label

- Front & shoulder label

- Front-shoulder - back label

- Neck round label

- Orientation labelling

Features:

- Output: 2,000 to 18,000LPH

- Stepped motor for high speed

- No bottle – no glue – no label function

- Electronic bottle counter & bottle per minute meter with fault display unit

- Automatic speed synchronization of servo motors - Scroll spacing device.

- PLC Controlled

- Tool free change--over

- Label dispensing with servo motor device – Reel unwinding unit by spring lever – end of reel control stopmachine.

- Steep feeding of Labels allowing for empty spaces on real-Missing label control on Reel.

- Label smoothing system with a “ mouse ” rubber application.

- Micrometric adjustment of the overprint position of the labels.

- Safety Devices in accordance with EC Regulations

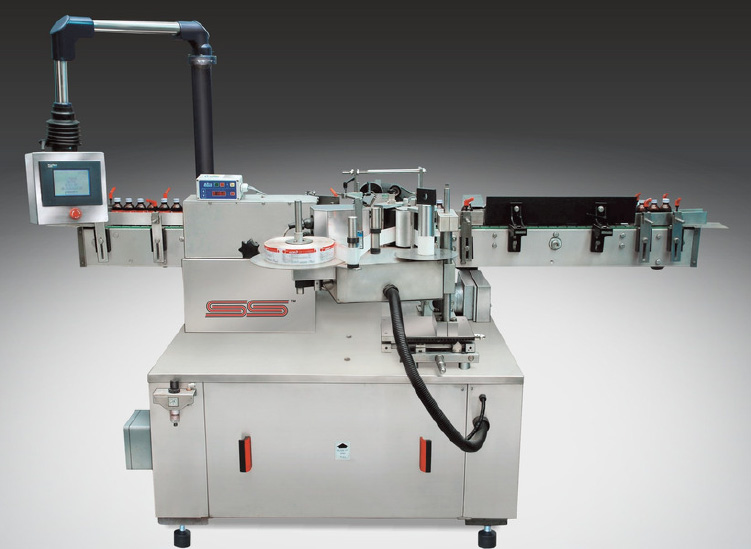

LINEAR LABELLER

This machine is a low speed linear machine, highly cost effective with output ranging between 1,000 – 3,000 bottles per hour and can handle different type and size of bottles and labels. Techmatic is very efficient and can handle all type of glass and plastic bottles / containers ( cylindrical / non-cylindrical & odd shaped) with various pressure sensitive labelling applications.( 1 – 2 labelling station options)

Label Type:

- Self-adhesive

- Wet glue

Label Positions:

- Front label

- Front & shoulder label

- Front & back label

- Overlap label

Features:

- Output: 1,000 to 3,000LPH

- No bottle – no glue – no label function

- Electronic bottle counter & bottle per minute meter with fault display unit

- Automatic speed synchronization of servo motors - Scroll spacing device.

- PLC Controlled

- To free change over

- Label dispensing with servo motor device – Reel unwinding unit by spring lever – end of reel control stop machine.

- Steep feeding of Labels allowing for empty spaces on real-Missing label control on Reel.

- Label smoothing system with a “mouse” rubber application.

- Micrometric adjustment of the overprint position of the labels.

- Safety Devices in accordance with EC Regulations