End Packaging

End Packaging

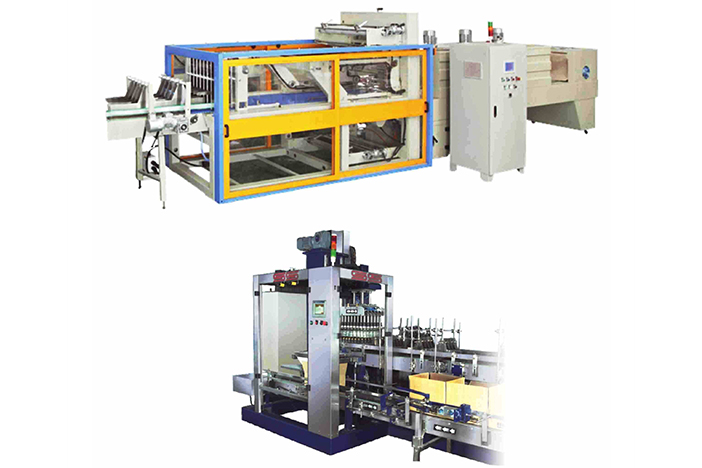

We can provide a number of machines for end packaging as per customer requirement for size and speed variant which include:

Case Erector

We can provide case erectors as per your requirement of case size and speed configurations.

Typical Technical Parameter:

- Capacity : 8-12 Cases / Minute

- Case Dimensions : L 200-650 mm

- W 150-450 mm

- H 150-400 mm

- Frame : Carbon Steel, baking varnish

- Installed Power : 380V 50/60Hz, 1 KW

- Pressure of Compressed Air : 0.5-0.6MPa 30L/Min

Machine Descriptions:

- Standard carton blanks is good for steady conveyance

- It may be lengthen for increasing the storage according to demand

- 90 degree stack preparation of carton blanks

- Suitable for different quality cartons

- Short change-over time to another carton forming and sealing

- Reducing labour requirements

- Easy to operate and adjust

- Hot melt glue model is available

- Easy connection to case packer & case sealer

- Safety Devices in accordance with EC Regulations

Case Packer (Pick & Place)

We can provide case packer suitable to handle various type of bottles, jars, cylindrical and odd shaped cans.

Features:

- Bottle collator by means of S.S slat chains or suitable material so as to provide bottle base grip

- An electronic (PLC) operating system controls for sensing presence and position of bottles.

- Centring unit `CHASERS' positions the cases

- Pneumatically operated bottle gripping heads (numbered as per the number of bottles in a case picks up bottles from the bottle collator and inserts them through the chasers and places them gently into the case by means of electro mechanical translation movements

- Speed, can be adjusted (on lower side) by variable frequency drive & conveyor sensor system

- Safety Devices in accordance with EC Regulations

Case Sealer

Carton Sealer is an adjustable machine which is pre-set as per the size of case and seals the carton from both top and bottom by BOPP Tape. Machine has inbuilt gravity rollers at both the infeed and outfeed for smooth and easy movement off cartons before and after sealing. The sealing heads are carried on columns, allowing rapid and precise stetting for size change and giving mechanical rigidity.

- Self-centring slide guides are provided for accurate centring.

- Operation height adjustment up to 250 mm.

- No Tape Wastage.

Features:

- Sturdy construction reliable and robust design

- Indigenous design and components

- Change over to various carton sizes with in minutes

- Easy change to tape rolls & dispensers

- Easy adjustment off tension on tape for even, uniform and wrinkles sticking off tape without any breaking

- PLS interface system

- Speed as desired

- Safety Devices in accordance with EC Regulations